The adoption of the competitive bidding framework for the allocation of solar power projects has led to a significant reduction in the solar tariff levels. It has reduced developer margins and made returns unsustainable for the majority of the stakeholders involved. This may soon create a scenario where cost-cutting measures may be adopted for improving margins and compromising on project quality may become a common practice. To address some of these issues and highlight the impact of poor quality on project performance, a study was carried out by PI Photovoltaik-Institut Berlin AG (PI Berlin), on behalf of the Physikalisch-Technische Bundesanstalt (PTB).

The “Pilot Study on Quality Aspects of PV Power Plants in India” was conducted to analyse the present status of operational solar photovoltaic (PV) plants installed in India. It is a part of the “Strengthening Quality Infrastructure for the Solar Industry-India” project, funded by the German Ministry for Economic Cooperation and Development and executed by PTB. The following is a brief summary of the report…

Aim of the study

With the increasing size and scale of solar power projects in India, the solar market has become quite profitable for all stakeholders. At the same time, the risks associated with environmental hazards, improper maintenance and poor project execution could lead to poor project performance in the long term, and lower returns. The present study aims to increase the awareness of solar project developers, lending institutions, engineering, procurement and construction (EPC) contractors and operators on project quality assurance.

PI Berlin published a final report of the study documenting the performance and safety-related conditions of the selected projects, and the major risks identified during the course of the study. The key lessons and risk mitigation measures have also been highlighted in the report. These lessons and statements on project quality have been translated into recommendations for the solar industry in line with the country’s target of 100 GW of installed solar capacity by 2022.

Study methodology

For this study, six projects installed in the recent years were selected and inspected from July 3, 2017 to July 14, 2017. The selection of the projects was undertaken with support from the Solar Energy Corporation of India and KfW, in cooperation with the Ministry of New and Renewable Energy and the National Institute for Solar Energy in India. These projects were selected to represent all stress factors in different climatic zones, the various modules and mounting structure technologies used in the Indian market, and cover the states with the highest cumulative solar capacity. Of the six projects, two were rooftop projects, a 200 kW project in the North and a 1,505 kW project in the Northeast, and four were ground-mounted – a 50 MW project and a 100 MW project in the Northwest, a 30 MW project in the central region and a 10 MW project in south India.

These projects were evaluated using a technical due diligence product developed by PI Berlin for assessing operational assets. The evaluation methodology was based on the assessment of seven parameters – contracts and warranties, PV plant design, electromechanical installation quality, commissioning completeness, system performance, module quality and operations and maintenance (O&M). Each of the six projects was analysed and audited on the basis of these parameters to record its actual operating condition.

Major risks and lessons learnt

Major risks and lessons learnt

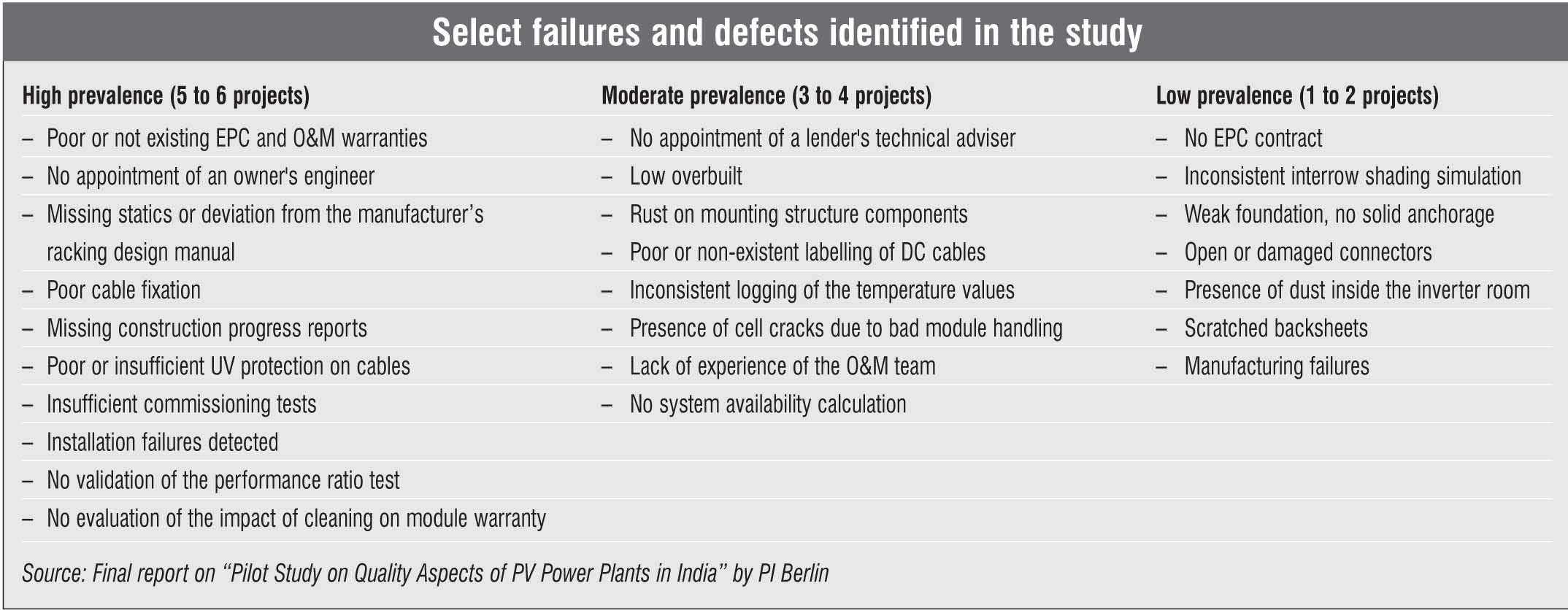

The results obtained from the study highlight serious faults in the development, execution and operation of solar projects in the Indian market. Component selection, installation, commissioning in compliance with all the test procedures, warranties and guarantees, and O&M are some of the areas that need urgent attention in EPC and O&M contracts. The study finds that the lack of clarity in contracts including vague guarantees can lead to huge investment losses in the long term.

Developers and contractors should not cave into price pressures and neglect the quality of PV modules. Problems such as faulty electrical joints and cracks due to improper handling of modules during transport, installation or O&M should be avoided at all costs to prevent any decline in the project performance. Even the system design and installation should not be singularly focused on lower capital cost, as it can have long-term implications for project profitability. In fact, project installation should be carried out as per industry best practices, which should be clearly laid out in the tender document. Efficient O&M is as important as proper installation and commissioning of a solar project to ensure greater performance gains throughout the project lifetime. It was found in the study that preventive maintenance in most solar plants is restricted to generic electrical components and is not solar PV specific. This should be avoided and a corrective maintenance methodology should be developed, which focuses on root cause analysis and prevention of repetitive failures. Apart from this, strong O&M reporting is essential for accurately monitoring and tracking the performance of solar PV plants. Apart from quality issues, projects in certain areas of India undergo immense environmental stress. Factors such as salt, heat, sand, strong winds and high ultraviolet radiations affect the performance of solar projects and lead to outages. To overcome these issues, projects should be designed to suit their geographical conditions.

Even with a high solar radiation and participation from both the private and government sectors in solar power development, projects are suffering from poor quality issues. This has put investment worth millions of dollars at risk. This can be attributed to the compromises on project quality to achieve the lowest tariffs. The study suggests the adoption of strict but affordable measures to mitigate the risks arising from inaccurate component selection, improper design, installation and commissioning, or inefficient O&M. Poor quality measures can severely impact the long-term profitability of a large number of solar projects in the country.