India has roughly 36 GW of installed solar power capacity as of August 2020, almost entirely made up of solar PV technology. It has taken the country over five years to build this capacity from just 7 GW by the end of 2015-16, making it one of the top five countries in terms of solar installations. The Indian solar industry has taken advantage of the global decline in solar panel prices to expand its solar capacity. Moreover, by awarding contracts to multiple private developers through mega auctions, a competitive industry structure has been created, with tariffs declining to less than Rs 3 per unit. This has been made possible with an enabling set of policies and regulations.

While detailed regulatory frameworks exist for solar planning and deployment, there are no mechanisms in place for the safe disposal of solar waste. Unless prompt action is taken, this might lead to huge problems in the future, considering that the country has ambitious plans to have a net installed solar power capacity of 100 GW by 2022, 350 GW by 2030 and 1,000 GW by 2050. Against this backdrop, the paper “Need for Legal Compliance for Safe Solar Energy Waste Disposal”, explores the projected PV waste volume that will be generated in the future and the approaches to address the PV waste disposal problem in the country. Renewable Watch presents a brief summary of the paper…

Composition of a solar PV module

The bulk of solar PV modules used in India are crystalline silicon, which are made of glass and aluminium. Other components include copper connectors, polymer-based adhesive encapsulation layer, backsheet layer, silicon metal solar cells, silver, and other metals like tin and lead. Some of these components are potentially hazardous like polymers and antimony, which is present in glass. The polymer material used in backsheets and encapsulants is made of ethyl vinyl acetate and polyvinyl fluoride. These polymers cannot be recovered and are typically incinerated, although they can also be safely evaporated at 500 degrees Celsius using thermal processing. There is a risk of antimony leaching from glass when the glass exposed to ultraviolet radiation or sunlight is put in wet conditions. Thus, in March 2019, the Ministry of New and Renewable Energy drafted the blueprint for environmentally safe handling, recycling and disposal of the glass used in PV panels.

Module waste projections

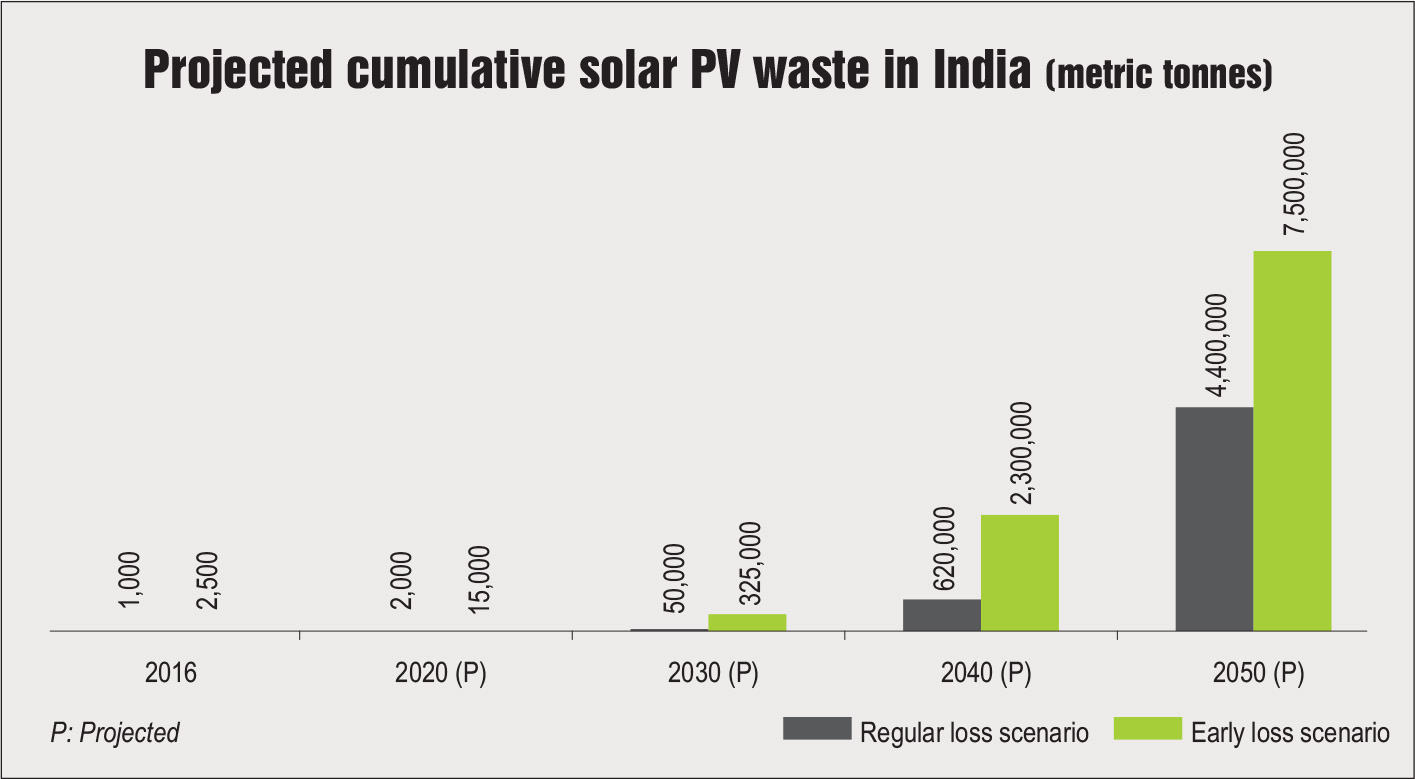

While modules have warranties of 25-30 years, good quality products can last longer. Given the insatiable demand for solar modules over the past few years, the market has been flooded with low quality modules that are cheaper than high quality ones. With tariffs plunging lower and margins narrowing, developers and contractors have had to cut corners and opt for cheaper modules, which are prone to losses and may degrade faster than good quality modules. Thus, waste generated from PV modules is analysed under two scenarios – regular loss after 25-30 years and early loss due to qualitative issues and repowering. In the first case, modules are usually discarded as waste after 25 years, that is, at the end of their life. The volume of solar PV waste in India under regular loss can be estimated considering a standard 25-year life.

However, in the second case, modules may suffer degradation due to any of these causes – glass breakage, defect in J-box and cables, power loss, delamination, transport damage, loose frame, optical failure, and defective cell interconnect. Thus, these modules have to be discarded and replaced with new products. Further, repowering of solar modules with high efficiency cells can be undertaken by developers to improve efficiencies. It is quite difficult to estimate the exact volume of PV waste in this case since it is uncertain how many modules may suffer from defects and become unusable before 25 years.

As per a June 2016 study by the International Renewable Energy Agency–International Energy Agency Photovoltaic Power Systems Programme, Task 12, India will have roughly 4.5 million metric tonnes (mmt) of PV waste by 2050, which may reach 7.5 mmt under the early loss scenario.

Tackling PV waste

For making a crystalline solar cell, silicon feedstock is processed into wafers. These wafers are then used to make cells. A complete solar module has other components as well such as glass, aluminium frame, lamination, mounts and cable. Almost 80 per cent of the raw material used for making a solar panel can be recovered and used for making new panels. Thus, careful tackling of PV waste and proper recycling practices can help in minimising the extraction of new materials to a large extent. The paper estimates that 240,000 MW of new panels can be reproduced through recycling of waste panels without having to extract new materials.

As per the study, the carbon footprint for the entire product ranges from 21 kg to 29 kg per MWh, and 50 per cent of this goes into converting raw material into finished products. Thus, this 50 per cent of the 3,000 tonnes CO2 per MW can be avoided by solar panel recycling, which will result in an overall CO2 reduction of 360 billion tonnes in the product lifetime. Hence, solar PV recycling will not only help in effective tackling of waste, but will also enable the abatement of CO2 emissions.

The paper recommends certain key action points for the disposal of PV waste:

- Similar to the Waste Electrical and Electronic Equipment directive of the European Union, India should have policy guidelines for solar waste management since the components of solar modules are not biodegradable.

- Identification of causes and prevention measures for defects and early losses in solar modules.

- R&D for viable recycling mechanisms as compared to landfilling.

- Recycled PV panels must be looked at as a raw material for producing new modules.

- Solar PV modules must have a built-in recycling cost.

- The volume of PV modules that can be reproduced from waste material should be calculated.

- A careful analysis of greenhouse gas emissions for making a new PV module as against recycling waste PV modules.

- Responsibility of solar panel recycling should lie with the end user.

- Analysis of job opportunities that can be generated from recycling PV modules.

Outlook

Landfilling 4.5 mmt of PV waste in the regular scenario and 7.5 mmt in the early loss scenario is a possible option for tackling the massive solar garbage. However, it is perhaps not the most sustainable option. Solar PV waste should instead be mandatorily recycled, and strict government norms should enforce that. Moreover, business models should be developed taking transport and logistics into consideration to make solar panel recycling more viable. The government and the solar industry should work in coordination with the aim of achieving maximum recovery of the components used in making PV modules. This would not only help in reducing import dependence to a substantial degree but also ensure a truly clean and sustainable circular solar economy.

Based on a paper, “Need for Legal Compliance for Safe Solar Energy Waste Disposal”, by Jaideep N. Malaviya, Managing Director, Malaviya Solar Energy Consultancy