Introduction

Bifacial is gaining traction globally and is expected to get majority of the market share over the next few years as confidence is established on the technology and higher generation.Bifacial modules have traditionally been front glass-back glass (G-G) structures owing to lack of good transparent backsheet (G-B) options. Introduction of transparent backsheetswith field proven Tedlar® PVF film provides a reliable solution.

Benefits of Glass-Transparent Backsheets (G-B) over Double Glass(G-G)– Lower cost of ownership

| Benefits | Reason |

| More Reliable and Durable | · >35-years of field proven glass-backsheet structure

· Lower power degradation rate · Lower risk of PID |

| Better generation | · G-G panels operate 1 – 3°C higher than G-B Solar Panels |

| Lower installation & O&M cost | · No change in structure design and weight

· Lighter weight enables easier installation, and lower labor cost · Less risk of breakage during transportation and installation |

| Lower manufacturing cost | · No change in manufacturing process – no additional capexinvestment

· Higher yield rate (More fragile G-G is prone to cracking during manufacturing) · Faster lamination speed enables more production |

Evolution and Field Performance: G-Gvs. G-B Solar Panels

G-Gsolar panelshave been in use for a few decades now. Gen 1 G-G solar panelshad 3.2 mm fully tempered glass (front and rear) and an aluminum frame. However, they exhibited high power degradation due to cell corrosion and encapsulant browning and delamination in the studies conducted by JRC and DuPont, respectively. JRC has reported an average annual degradation rates of ~1.3% and ~0.3% in double glass and glass / Tedlar® backsheet solar panels (aged between 19 – 23 years), respectively [1]

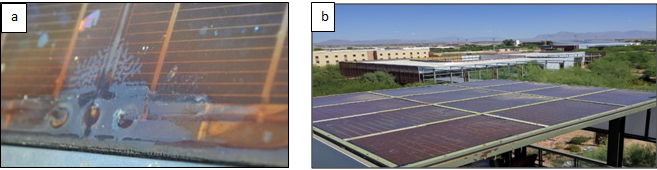

The primary reason for this high degradation in G-G structures is the entrapment of moisture (whichseeps in through the edges of the modules), that gradually corrodes the metal contacts,cells and accelerates power loss (figure 1). However, breathable backsheets allow for quick ingress and egressof the moisture,preventing its water entrapment inside the panels.

Figure 1: a. 15 years old plant with double glass in China, severe encapsulant browning and corrosion, 100% power loss, b.10 years old plant with double glass in USA, encapsulant discoloration and delamination, plantdecommissioned due to high power loss

Figure 1: a. 15 years old plant with double glass in China, severe encapsulant browning and corrosion, 100% power loss, b.10 years old plant with double glass in USA, encapsulant discoloration and delamination, plantdecommissioned due to high power loss

Next generation G-Gsolar panelswere launched around 2017,albeit with a few changes – 3.2 mm thick fully tempered front and rearglasses were replaced with 2.5 mm thick heat strengthened glasses and were frameless– to minimize the weight and the cost. However, these design changes led to massive failures (bending and glass cracking)in less than 2 years in the field (figure 2).This prompted inclusion of frames, which increased the cost, weight and more susceptibility to PID.

In the current generation G-Gpanels, thinner 2 mm heat strengthened glass (HSG) is used to reduce weight.However, HSG increases the risk of glass cracking due to snow and wind loads and hot spots.

Figure 2: a. Bending of double glass panels in ~15% panelsafter 1 year, b. Cracking of double glass panels in ~10% panels after 2 years

Figure 2: a. Bending of double glass panels in ~15% panelsafter 1 year, b. Cracking of double glass panels in ~10% panels after 2 years

G-B structures especially those with Tedlar® based backsheets, are field proven over more than 35 years and have demonstrated low degradation rates across different applications, geographies and climates.

Conclusion

Bifacial technologies with their higher yield are expected to gain share in the near term. The stakeholders are striving to establish robust solutions for the front and rear layers: balancing the variables of efficiency improvement, higher weight and reliability requirements. G-G panel structures traditionally preferred for bifacial continue to extend challenges for the manufacturers and developers.

A new development: Glass –transparent (clear)Tedlar® based backsheet (G-B) structure, with its lighter, mechanically stronger and easier to install advantagesprovide a reliable alternative and is increasingly gaining acceptance globally.

References

- Joint Research Centre (Italy)