India has witnessed massive uptake of solar power in recent years, with installed capacity only a few megawatts away from the 30 GW mark. The constantly increasing size and scale of these projects points to the importance of proper operations and maintenance (O&M) of solar power plants. O&M considerations are more crucial for a nation like India, which has certain peculiarities that are absent in developed nations. For instance, solar power plants in India have high security requirements due to a constant fear of thefts in remote areas. The temperatures are much higher when compared to the United States and countries in Europe. Higher temperatures are known to impact module health and performance. Dust levels are also high, especially in the dry northern states, and this requires frequent module cleaning to prevent soiling losses. Other local issues such as grid curtailment and lack of skilled manpower crop up in many solar power plants, especially those located in remote areas.

India has witnessed massive uptake of solar power in recent years, with installed capacity only a few megawatts away from the 30 GW mark. The constantly increasing size and scale of these projects points to the importance of proper operations and maintenance (O&M) of solar power plants. O&M considerations are more crucial for a nation like India, which has certain peculiarities that are absent in developed nations. For instance, solar power plants in India have high security requirements due to a constant fear of thefts in remote areas. The temperatures are much higher when compared to the United States and countries in Europe. Higher temperatures are known to impact module health and performance. Dust levels are also high, especially in the dry northern states, and this requires frequent module cleaning to prevent soiling losses. Other local issues such as grid curtailment and lack of skilled manpower crop up in many solar power plants, especially those located in remote areas.

These factors have led to the emergence of a large number of specialised O&M service providers for solar power plants. These O&M contractors offer customised service packages to solar power developers at competitive rates. Third-party O&M is a boon for developers having solar projects in remote locations, as this allows them to concentrate on other aspects of their business. These service arrangements can be of various types and durations. For instance, comprehensive O&M services with mean-time-to-repair guarantees, free spare parts replacement and 24×7 support can cost about Rs 0.55 million per MWp. Developers can also opt for a limited spares arrangement, which would entail a cost of about Rs 0.4 million per MWp or a service call model for about Rs 0.2 million per MWp.

Key O&M challenges

Even with specialised O&M services, a number of challenges have emerged that are impacting the performance of solar power plants in the long run. One of the major issues faced by operators is water shortage at project sites. With many solar power plants located in drought-prone and desert-like areas, non-availability of water for cleaning modules is going to pose a huge challenge in the future. The Central Ground Water Authority’s check on groundwater usage is further going to complicate matters. Another challenge faced by developers is related to inverter O&M. There have been instances of equipment manufacturers going out of business during the equipment lifetime, leaving installed inverters with no service and spares support. The lack of skilled and trained manpower for operating and maintaining these plants is another major constraint. Many operators, who spend a lot of time and resources on training local technicians in good O&M practices, find retaining the manpower a tough task. Also, quality control at substations and module cleaning technologies are still evolving.

Best practices and the way forward

Developer experience all over India shows that exhaustive O&M contracts and detailed service-level agreements are of paramount importance to ensure that all aspects related to solar plant performance are taken care of. Thus, all the services to be provided by an operator should be mentioned in detail, along with the frequency of each activity and comprehensive documentation. Apart from this, reliable and responsive monitoring systems should be installed in solar plants, and any faults or defects quickly addressed. Developers should ensure that modules are monitored and cleaned regularly, and frequent performance and degradation diagnosis is done for all equipment. A spare parts inventory should be maintained at site along with stringent mean-time-to-repair guarantees from operators so as to reduce project downtime and revenue loss.

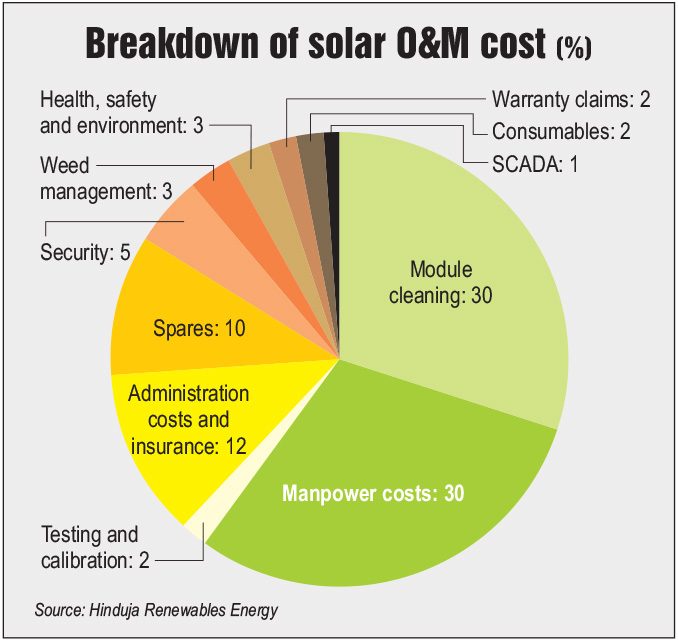

Apart from these best practices, developers themselves can increase the role of automation in their solar power plants. Overall, module cleaning and manpower costs together constitute the bulk of solar plant O&M costs in India; these costs can be significantly reduced with automated processes such as robotic cleaning solutions and aerial drones for site inspection. They can use more efficient and artificial intelligence (AI)-enabled monitoring platforms for predictive O&M. Many developers are already using advanced asset management software with AI for optimising and analysing project data from multiple projects and improving performance. Some software companies are developing accurate weather forecasting services to predict future generation, while others are providing machine learning software to enable projects to self-diagnose and rectify faults. This trend is going to continue in the future as developers and operators reduce manpower costs and increase project efficiency through automation and digitalisation.

Based on a presentation by Colonel Sudhanshu Kamboj, Chief Operating Officer, Projects and Operations, Hinduja Renewables Energy Private Limited.