As the Indian solar power sector grows in volume, the pressure to maintain sustainable margins is also increasing. This can be attributed to greater fall in tariffs as compared to that in capital and financial costs. The industry is, therefore, looking to improve efficiencies across the value chain. Solar modules account for about 60 per cent of the total project costs, making them a critical component for efficient operations. The module technology has evolved over the years with a strong focus on improving the efficiency of solar power plants to increase the yield and, in turn, revenues. From monofacial to bifacial, monocrystalline to mono-passivated emitter and rear cells (mono-PERC) and bifacial mono-PERC, modules have come a long way.

Bifacial modules

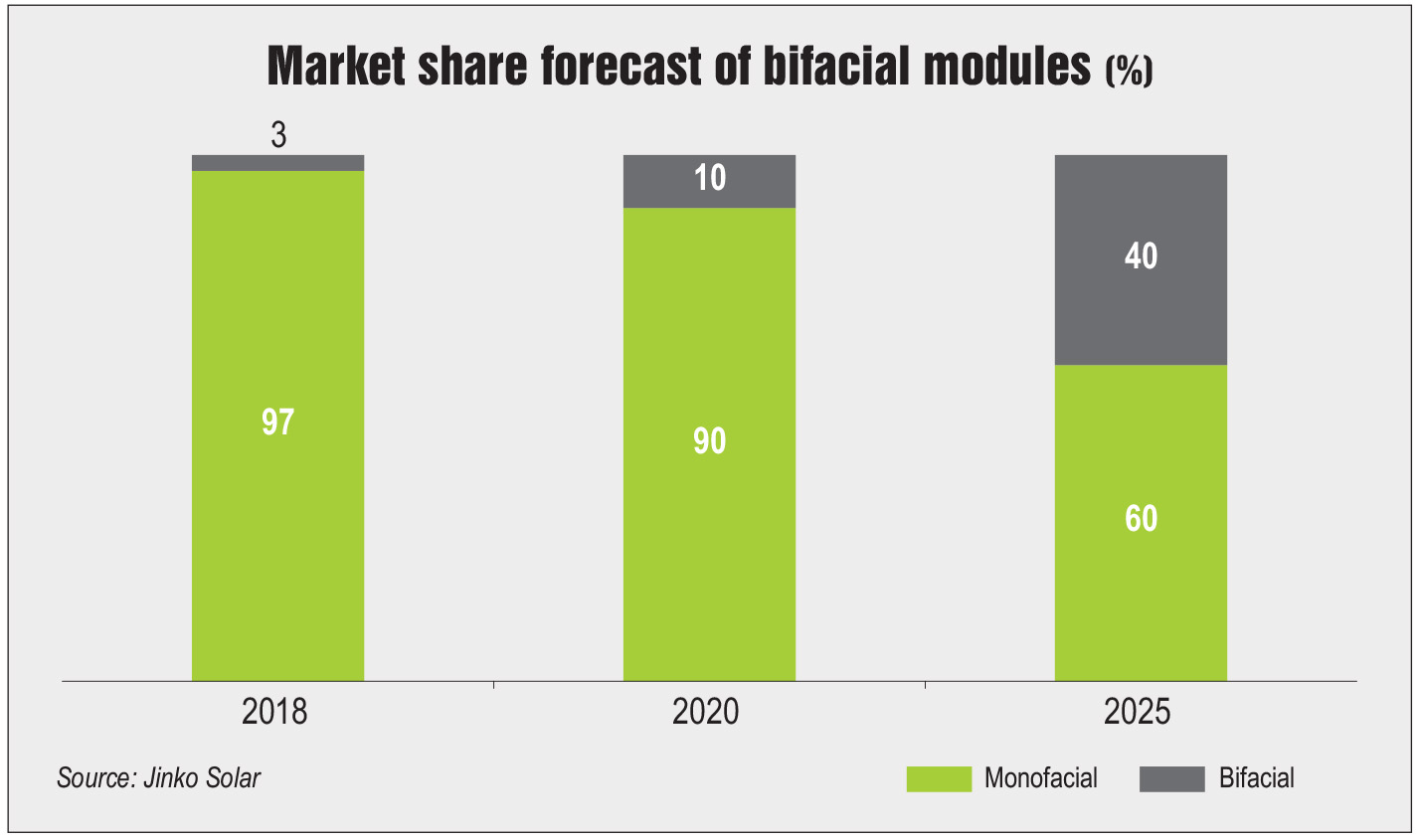

Bifacial modules, as the name suggests, are able to generate power from both sides of the module as opposed to monofacial modules. As per Sai Charan Kuppili, technical director, South Asia Market, Jinko Solar, the energy gains can be as high as 25 per cent. While the backsheet in monofacial modules is white, that of bifacials is transparent, allowing the sunlight to pass through to the ground. The light is then reflected from the ground to the second face of the module, which also generates energy. To make bifacials more effective, the albedo has to be high. Albedo is a measure of the reflection of solar radiation out of the total radiation received by the ground. Soil moisture content, thermal diffusivity, and light incident angle are critical factors that affect the albedo and, in turn, bifacial energy gains. Kuppili expects the market share of bifacial modules to increase significantly to reach 40 per cent by 2025, as compared to around 3 per cent in 2018.

While the energy gains are similar across all kinds of bifacial modules, those with transparent sheets are lighter in weight and have lower balance of system (BoS) costs than bifacials with dual glass sheets. It is important that the transparent backsheet must have high transmission and anti-ultraviolet (UV) capability. Taking the backsheet technology further, Kuppili says that introducing a mesh layer in the backsheet can enhance front-side generation by around 5 watts per module. This type of backsheet has one more mesh layer with high reflectivity and UV resistance. Further, fewer supporting structures are required for bifacials with transparent backsheets as compared to those with dual glass. This helps save mounting construction costs by 15 per cent. The energy gains from backsheets vary with the albedo. On white paint, the albedo is the highest, hence the largest energy gain of 19 per cent. On sand, it is around 9 per cent. Bifacial modules installed on cement or grass deliver yield gains of 7 per cent as compared to monofacial modules under similar conditions.

According to Rahul Bhardwaj, head, business development, L&T Solar, using bifacial modules in conjunction with trackers can lead to greater energy yields. The tracking ensures that there is optimal, direct normal irradiance absorption on the front side. On the rear side, the tracker enables higher view factor gains for higher albedo values. Pilot projects have demonstrated significant gains by using bifacial modules as opposed to monofacials. As per Bhardwaj, an L&T project located at Kanchipuram with a surface of red soil and grass, and fitted with bifacial modules can result in average yield gains of 17.73 per cent across eight days.

Mono-PERC

According to Dr Rahul Kapil, vice-president and director, LONGi Solar, the company’s mono-PERC cell efficiency reached 24.06 per cent in January 2019. It breached the earlier mark of 23.6 per cent achieved in February 2018. In November 2018, the company was able to improve its mono-PERC module efficiency to 20.83 per cent. The mono-PERC solution is known to deliver higher power and energy yield while demonstrating low degradation. Moreover, these modules have lower hot-spot impact as compared to other technologies and greater backside energy yield. The result is greater efficiency and effective lowest cost of energy. When used in bifacial system design, mono-PERC modules are even more effective and lead to higher energy yield.

Bifacial modules require specific design parameters in order to derive more rear-side power gain. These include higher albedo and module height, low ground coverage ratio, and low shading. Different ground conditions may provide different albedo yields, which are highest for snow, and lowest for dry asphalt and brown soil. As the albedo increases, the power gain also increases proportionally. For around 80 per cent increase in the albedo, the energy gain has been found to be as much as 30 per cent. As per Kapil, based on simulation, both increasing ground albedo and height can result in more power gain. Higher racking of modules improves backside energy yield and irradiance uniformity. Interestingly, the power gain begins to plateau at the rack height of 1 metre and peaks at around 2 metres. Kapil recommends a height of over 1 metre for effective backside energy yield.

Based on simulations and test results by LONGi Solar, increasing rack clearance or decreasing the thickness of the rack can reduce the optical loss of modules. To avoid rack shading, bifacial modules must be installed along the longer frame. In case the shading is unavoidable, rack clearance of greater than 40 millimetres is recommended. The c-side of short frames is removed to improve the energy yield. Simulations and test results demonstrate a power gain of 0.6 per cent without the c-side of the short frame. The field data for one year showed 10.6 per cent of backside energy yield for a project with concrete at 1 metre height, and 22.6 per cent with thermoplastic polyolefin at a height of 2 metres. The project, located at Taizhou, China, has a capacity of 2.8 kW and is fitted with bifacial PERC with fixed tilt.

Conclusion

As compared to the monofacial fixed tilt solar power plant, bifacial fixed tilt plants provide about 8 per cent greater energy yield. However, this comes at an incremental system cost of 10 per cent. A solar power system with bifacial modules and trackers will lead to an energy gain of about 25 per cent at an incremental cost of 20 per cent. While lower system costs will only improve the developer’s bidding competitiveness, higher energy gains will lead to better rate of returns. In the current tariff scenario in India, developers are seeking better margins from their projects. In this context, the return profile of monofacial modules is no longer competitive and bifacial mono-PERC, along with trackers, may become the future of the Indian solar market.

Based on presentations by Dr Rahul Kapil, Vice-President and Director, LONGi Solar; Rahul Bhardwaj, Head, Business Development, L&T Solar; and Sai Charan Kuppili, Technical Director, South Asia Market, Jinko Solar