By Khushboo Goyal

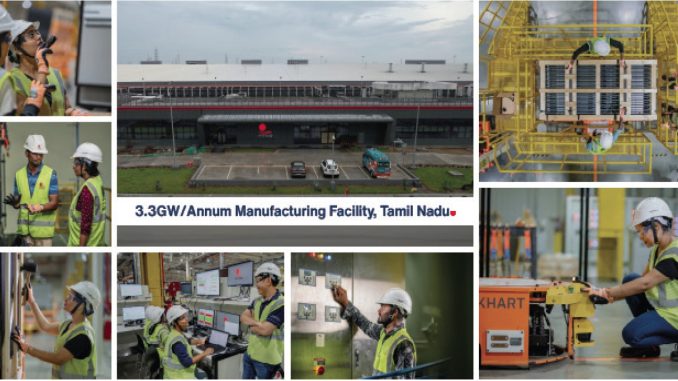

Arizona-headquartered First Solar set up its first solar manufacturing unit in India in 2023 with a massive 3.3 GW annual production capacity. One of the only companies of its scale in the world that makes thin-film modules instead of crystalline ones, it is also the only solar manufacturer from the western hemisphere, and specifically from the United States, that has set up a module manufacturing facility in India. Moreover, it has the distinction of being the only foreign company getting selected as a beneficiary of the government of India’s production-linked incentive (PLI) scheme Tranche-II, for setting up this facility in Sriperumbudur, near Chennai, in Tamil Nadu. Now, featuring on the Approved List of Models and Manufacturers (ALMM) of the Ministry of New and Renewable Energy, and also eligible for DCR solar projects, First Solar produces its Series 7 solar modules at this facility.

I had a chance to visit this colossal facility in Chennai that has a floor area of 2.5 million square feet, and was given a tour of the factory by Sujoy Ghosh, Vice-President and Country Managing Director, India. Alongside discussions on thin-film technology and the factory’s green agenda, we talked about the company’s global presence, the reason for selecting Chennai as the factory location, and the importance of supply chain security in the Indian solar power space. This article begins with highlights of First Solar’s global operations and then dives into the key specifics of the Indian facility such as project implementation and environment conservation efforts.

Background

First Solar was founded in 1999, with its first production line commissioned in Ohio in 2003. Today, the company has an aggregate name-plate capacity of 21.7 GW/annum with factories spread across the US, Malaysia, Vietnam and India. It is headquartered in Tempe, Arizona, and has a corporate R&D centre in Santa Clara and another one in Sweden. In 2007, the company built a factory in Frankfurt Oder, Germany, however, it had to be closed down by 2012, due to unviable environment, triggered by dumping of solar module into the European Union primarily by Chinese manufacturers, due to excess capacity from their home country.

While crystalline solar cells and modules continue to dominate the market, thin-film technology has witnessed an increase in demand in recent years, driven by a slow but steady transition towards ensuring security of supply chains. The dumping of solar cells by Chinese companies across the world, along with the sudden halt of cell and module supplies from Chinese factories during the Covid pandemic, made industries and governments aware of the need to diversify supply chains. Even so, China continues to dominate most of the global polysilicon production, which is the building block for a crystalline cell. As thin-film cells use cadmium and tellurium, which are basically impurities found in the ores of zinc and copper respectively, First Solar is not dependent on any one country for its raw material.

The focus on reducing the dependence on China for solar imports by expanding domestic manufacturing capacities has led to the adoption of various tariff and non-tariff barriers by many countries including the US and India. And, this has worked in First Solar’s favour which has set up two more factories recently, one in Alabama and the other under-construction in Louisiana, apart from the one in Tamil Nadu to cater to the growing domestic demand in these countries. It aims to reach 25 GW of annual production capacity by 2026 driven by the rising demand for thin-film technology.

The Chennai facility

Built in a time-frame of 19 months from ground-breaking, the factory’s formal inauguration was done in January 2024. Meanwhile, the facility commenced sales in November 2024 after securing the necessary local certifications like BIS. Apart from incentives from the Indian government in the form of PLI, the project was supported by the US International Development Finance Corporation (DFC), which financed $500 million out of the total investment of approximately $700 million. In addition, the company received significant support from the state government of Tamil Nadu, in the form of quick permits (which were granted within 35 days) through a single window portal, helping the company to start construction on time. Facilities such as high voltage power connection and water connection were also made available to the company on time.

There were a few other reasons for First Solar to select Tamil Nadu as the state and then zero in on Chennai for its first-ever facility in India, according to Ghosh. One, the facility had to be near a seaport as the company has to rely on imports of some portion of its glass requirement. The project site has three ports within a distance of 40-50 km – Chennai, Kattupalli and Ennore. Two, Tamil Nadu has a has a good land bank, a stable industrial policy with structured state incentives like capital subsidy, and various private industrial clusters already developed. For instance, one of First Solar’s global glass suppliers, St Gobain, is located close by. Three, this project site was already permitted for a red category industry. Four, the state has a very well-developed ecosystem of engineering colleges, which helped the company find the right talent for its project, especially considering the fact that its goal was to have 50 per cent gender diversity in the workforce. It was pertinent to select a city and seaport combination as the company had to not only find the right talent but also nurture and retain it.

Interestingly, this solar manufacturing facility is reportedly the world’s first net-zero water withdrawal solar module production unit. Built in an area of high baseline water stress, it entirely relies on water from Chennai’s Metrowater TTRO plant. The water is treated through reverse osmosis. In addition, it is a zero-wastewater discharge facility. To further adopt the principle of circularity, the facility has a solar PV recycling plant. While many of the materials such as aluminum, glass and laminates are recovered using established practices, the facility employs a closed-loop semiconductor recovery technology that helps recycles cadmium and tellurium from scrap modules.

Staying on track towards achieving its green manufacturing goals, First Solar has tied up with Cleantech Solar to source 7.3 GWh renewable energy from the latter’s intrastate solar-wind hybrid project coming up in Tamil Nadu. First Solar has taken 26 per cent equity in this group captive project, which will meet 50-70 per cent of the factory’s energy needs, as per the 15-year power purchase agreement signed between the two companies in January 2024.

Key takeaways

It was a highly enriching experience to visit this vast end-to-end solar production facility. The entire unit is built on 130 acres of land of which 33 per cent is green cover and the actual manufacturing facility encompasses about 2.5 million square feet of the total area. Interestingly, the factory is fully automated, and the modules are not touched by human hands during the production process, including packaging.

According to Ghosh, it takes 4.5 hours to convert a sheet of glass into a module in this thin-film module producing factory, and every 5 seconds a module comes off the line. As we explored the factory on our golf cart, we tracked the module’s journey from a glass pane to a completed module being packed and stored, as it travelled through 4.5 km of conveyor belts!

As India focuses on enhancing its energy security by reducing imports and promoting domestic manufacturing of clean energy equipment, this 3.3 GW First Solar manufacturing facility ticks some of the key boxes in this journey. First, the company does not depend on Chinese imports for producing its solar modules. Second, it co-develops all of its process equipment with its manufacturing partners through shared intellectual properties; this helps it in creating a captive and controllable ecosystem for the future. Third, the company’s focus is on localising the connected component ecosystem such as glass, frame and other bill of materials, by getting its global suppliers to India or tying up with domestic suppliers who can supply to the facility. Finally, First Solar is adopting circular economy principles through recycling, green energy procurement and net-zero water withdrawal practices, which sets a benchmark for future clean energy manufacturing units in the country, in turn, paving the way for the sustainable growth of India’s manufacturing capabilities.