The rapid growth of solar photovoltaic (PV) installations worldwide has increased the focus on ensuring the safety, reliability and optimal performance of these systems throughout their lifespan of over 25 years. While solar modules and inverters serve as the core components and receive the most attention, the balance of system (BoS) components that make up the electrical infrastructure are equally important. As PV module prices keep falling, BoS components account for an increasing portion of the total system cost.

BoS components, such as cables and connectors, play a vital role in collecting and transmitting the direct current (DC) power generated by PV modules and delivering quality alternating current (AC) power safely to the grid. However, these components are often a major source of faults, fires, power loss and underperformance in PV systems.

In this article, Renewable Watch examines these components, common challenges and failure modes, applicable standards and best practices to ensure their safe and reliable operation.

DC and AC cabling

PV installations use special solar cables to interconnect modules and transmit the DC power generated to inverters. These include 4-10 mm2 PV wires or USE-2/RHW-2-rated cables for module interconnections and string cabling, larger 10+ mm2 single-core DC cables for main DC power transmission to inverters and multi-core armoured AC cable for AC power evacuation from inverters to transformers and the grid.

The key requirements for these cables are high current carrying capacity, double insulation, UV resistance, flexibility and voltage rating (typically 1.5-2 kV for DC). Copper conductors were traditionally used, but aluminium cables are gaining popularity due to their lower cost. However, aluminium has lower conductivity, requiring larger cable sizes.

Common DC cabling issues include under-sizing of cables, leading to higher voltage drop and power loss; improper sealing/ingress protection, leading to water ingress, insulation damage and ground faults; damage and corrosion of improperly routed or supported cables, loose or improper termination, causing overheating and arcing; material mismatch between aluminium cables and copper connectors/lugs, causing galvanic corrosion; and the use of non-solar-rated cables or poor quality unarmoured cables.

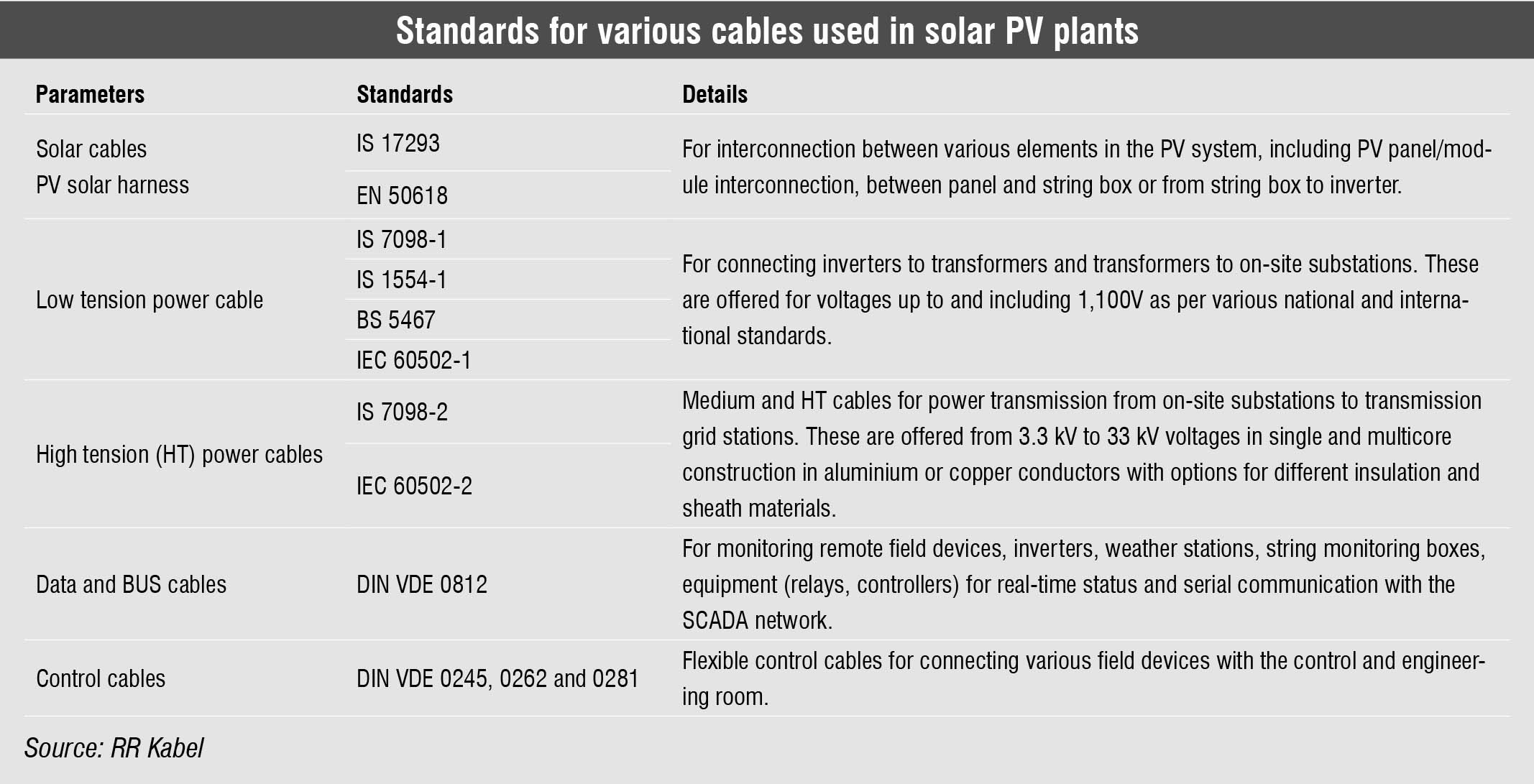

To avoid these issues, it is important to size cables according to voltage drop limits, current ratings and required de-rating factors as per standards; use double-insulated, solar-rated cables that comply with standards such as EN 50618 and IEC 62930; ensure compatibility of cable and connector materials; provide proper cable support, conduits, trays and sealing to prevent damage; follow manufacturer-recommended practices for crimping and termination; and route cables to minimise voltage drop and mechanical stresses.

PV connectors

PV connectors enable plug-and-play electrical connections between modules, strings and inverters without hard wiring. MC4 connectors, pioneered by Multi-Contact (now Staubli), have become the industry standard. However, the market is flooded with “MC4-compatible” products that may not be fully compatible and are a common cause of failures and fires.

Typical connector construction involves crimping the male pins and female sockets to cable ends and twisting the two parts together to lock them. Contact materials are typically copper, tin-plated copper or silver-plated copper.

Major connector failure modes include poor crimping, leading to high resistance and overheating; improper mating, leaving gaps and moisture ingress paths; material degradation and corrosion from environmental exposure; and the use of incompatible or counterfeit components.

Best practices for connectors include using certified, high-quality connectors from reputable manufacturers, avoiding mixing connectors from different manufacturers unless specifically allowing cross-mating, using manufacturer-specified crimping tools and processes, ensuring full insertion and locking of connectors, protecting unmated connectors with sealing caps, locating connectors to avoid mechanical stress, allowing access and preventing submersion and periodically inspecting for any signs of damage, overheating or improper mating.

Conclusion

Electrical infrastructure components such as cables and connectors are crucial elements in a solar PV plant. While less visible than modules and inverters, they are essential to performance, safety and long-term reliability.

Selecting high-quality certified products, following applicable standards and best practices in design and installation, and conducting periodic testing and thermography can help prevent common failure modes.

However, there are still gaps in standards for these components. Comprehensive engineering, procurement and construction guidelines and more specific technical requirements in tenders would significantly contribute to raising the quality bar across the industry. Training and certification of the growing solar workforce is also key to ensuring quality workmanship. Further, as solar rapidly scales to terawatt levels globally, independent reliability testing initiatives are necessary to maintain confidence.