In recent years, India has seen a paradigm shift towards solar energy. Owing to its sustainability goals and its push for greener, cleaner energy usage, the country has slowly been moving towards more sustainable energies such as wind and solar, and, more recently, photovoltaics (PV). The Indian government’s push towards renewable energy has made way for several new technologies and innovations such as battery technologies and solar panels.

PV is a fast growing market. The compound annual growth rate of cumulative PV installations, including off-grid, was 34 per cent between 2010 and 2020. In 2020, producers from Asia counted for 95 per cent of the total c-Si PV module production. China held the lead with a 67 per cent share. Europe had a share of 3 per cent; while the US/Canada had 2 per cent. Wafer sizes have increased, and by maintaining the number of cells, larger PV module sizes have been realised that allow a power range beyond 600 W per module. In 2020, Europe’s contribution to total PV installations amounted to 22 per cent (compared to 24 per cent in 2019). In contrast, installations in China accounted for 33 per cent. Si-wafer-based PV technology accounted for about 95 per cent of the total production in 2020. The share of monocrystalline technology is now about 84 per cent (compared to 66 per cent in 2019) of the total c-Si production. The market has shifted from being subsidy-driven to a competitive pricing model.

PV is a key cornerstone technology for the transformation of our energy system. Research on emerging PV technology encompasses dye-sensitised and perovskite solar cells, organic solar cells, photon management and tandem solar cells on crystalline silicon. The aim is to evaluate optimisation potential in PV with the help of these novel technologies, and to reduce the levellised cost of electricity. This includes improving the efficiency of well-established solar cells – for example of crystalline silicon – by improving their absorptive and reflective properties via advanced photon management.

Alternatively, processes and materials such as dye-sensitised and organic solar cells – although their efficiency is somewhat lower – offer clear potential for cost reduction. Basic research on organic solar cells addresses the fundamental properties of selective contacts and their implementation using inexpensive, durable raw materials and extremely thin films. The overall aim is to cooperate with industrial partners in developing stable coating and encapsulation processes on a roll-to-roll coater, which can then be used in full-scale equipment.

Recent developments

Silicon-based tandem solar cells

These cells make better use of the solar spectrum by reducing thermalisation losses. In addition to adapting the processes for Si bottom cells and developing tunnel contacts, work is also happening on new silicon nano-crystalline materials with adjustable band gaps and III-V-based absorber materials. The two single sub-cells are combined either by growing the top cell epitaxial directly on the bottom cell, or by wafer bonding. Further, work is being done on the development of perovskite and silicon layers for highly efficient perovskite-silicon tandem solar cells. Through this, photon management concepts are applied to ensure good current matching between the sub-cells.

Photon management

This area focuses on developing concepts, materials and technology to increase the efficiency of conventional PV technology by applying optical approaches. These include light-trapping structures such as diffractive gratings and scatterers, up-conversion, angular selectivity and spectral splitting. The investigated concepts are usually not restricted to a specific solar cell technology.

Multijunction solar cell

This solar cell is made of III-V and silicon semiconductor materials. This novel solar cell has a record power conversion efficiency of 46.7 per cent for a III-V concentrating PV cell with a four-junction architecture.

Organic PV

Organic PV (OPV) employs organic semiconductors such as polymers and oligomers to convert light into electrical energy. Due to its extremely low material consumption, zero heavy metal use and low temperature processing, the environmental impact of this technology is exceptionally low, and its energy payback times only amount to a few months. It also comes with the advantages of low weight and ultimate flexibility. All materials can be coated and printed with high throughput production methods at low costs, allowing solar cells to be designed in nearly arbitrary shapes. Moreover, the absorption spectrum can be tailored so that different colours can be realised; even neutrally tinted semi-transparent windows are possible.

Due to these outstanding properties, OPV is ideally suited for novel applications in important future markets such as the internet of things, building-integrated PV (BIPV) and agricultural PV. The worldwide effort in research and development has led to a dynamic evolution of the power conversion efficiency of OPV, which now exceeds 10 per cent for a variety of materials.

Integrated PV

Integrated PV blends into the outer surface of buildings, roads, railways and vehicles, such that the solar cells are often not visible from outside. Integrated PV shares land with agriculture, or floats on the surface of pit lakes created by flooding former open-cut mines. New types of technology and design options allow free choice of formats and colours for integrated modules, such that their connection circuits and cell architecture can be completely covered, if necessary. Specific requirements arising from their application, for example minimised weight per area or extremely high mechanical resistance, can be met with the choice of suitable materials.

BIPV and agrivoltaic applications alone offer enough potential space for 100 GWp of PV capacity. Moreover, integrated PV not only solves land use conflicts but also creates synergies including increased driving range; on-site building power supply; noise protection on roads and railways; better protection against hailstorms, drought and frost damage for agriculture; and reduced material consumption in buildings and vehicles. Integrated PV can thus make a significant contribution to achieving the renewable energy target, while making the energy transition a positive experience at the same time.

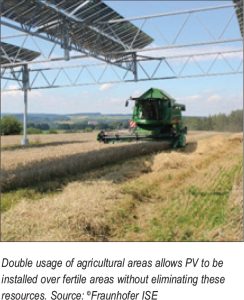

Agro-photovoltaics

This type of cell harvests power and produce from the sun, thus increasing land use efficiency. Energy transformation requires a massive expansion of solar electricity production, combined with a high space requirement. A problem for ground-mounted systems is that agricultural land is a very limited and valuable resource. Agrivoltaic solves this conflict by enabling food production and electricity generation in the same area. Through dual land use, agrivoltaic not only increases land efficiency but also increases the resilience of agricultural production to the consequences of climate change. Agrivoltaic provides farmers with additional income, and promotes the economic development of rural areas.

Vehicle-integrated photovoltaic

VIPV designates the mechanical, electrical and design-technical integration of PV modules into vehicles. The PV modules blend seamlessly into the vehicle exterior and are connected to electric loads or the drive battery in electric vehicles (EVs). Simultaneously, PV modules replace other components of the vehicle, for example, the roof or the bonnet. VIPV increases the mileage of EVs and improves their CO2 balance. The aesthetic expectations of integration of such modules into the vehicle design are especially high for cars. For utility vehicles (trucks and buses), lightweight PV modules are needed to avoid restricting the load capacity. Further application areas include caravans and mobile homes, delivery bicycles, trams, trains, ships, aircraft and drones.

Innovative coating for coloured PV modules

This model demonstrates the feasibility of producing colour-giving three-dimensional surface structures on large area cover glasses for PV modules. These solutions are inspired by nature. A phenomenon observed in the Morpho butterfly provided the starting point for our work. The beauty of the Morpho butterfly lies in its brilliant blue wing colour. Our coating consists of a dielectric material enabling high colour saturation, as well as good incident angle stability. The colour is individually adjustable for each glass. Right now, this coated cover glass for coloured solar modules is still in the prototype phase. The first test modules have already been manufactured. The next challenge is to optimise and scale up the production process to the industrial level in cooperation with module and glass manufacturers. There is no doubt that this technology will not only allow wider design variations for solar modules, but will also contribute to the broader acceptance of BIPV.