By Khushboo Goyal

While rapid expansion in solar photovoltaic (PV) deployments worldwide is under way, there is a massive thrust on developing the most efficient solar modules at competitive prices as well. Research and development in solar module production at present is focused on lowering production costs without compromising on system efficiencies. This is being achieved by reducing raw materials and consumables required for module production as well as enhancement in cell or module architectures. Moreover, ways to increase captured light and reduce module degradation rates are being explored to improve the overall system performance. This will, in turn, lead to an overall reduction in the levellised cost of energy.

In this regard, bifacial solar modules have emerged as a preferred technology to increase module energy output. These have the capability to capture sunlight from both sides of the module. In other words, they harvest the sunlight falling on the front side of the module as well as the light reflected from the ground and other modules on the rear side. This leads to a significant increase in power generation when compared to conventional monofacial modules. The Electric Power Research Institute of the US estimates a 50 per cent boost in power generation in highly controlled test conditions when compared to monofacial modules. Greater energy generation from the same solar PV capacity means greater sy-stem efficiencies, and hence, lesser capital and operational costs.

Bifacial modules are gaining prominence slowly, with even tracker manufacturers providing specially designed tracker models for bifacial modules. While the current uptake of bifacial PV cells is quite small, the International Technology Roadmap for PV predicts a 30 per cent market share for these cells by 2027. One of the factors contributing to its popularity could be the fact that almost all advanced cell concepts can be converted into bifacial to increase efficiency gains. In fact, bifacial cells are logical extensions of the already established and proven monocrystalline cell technology.

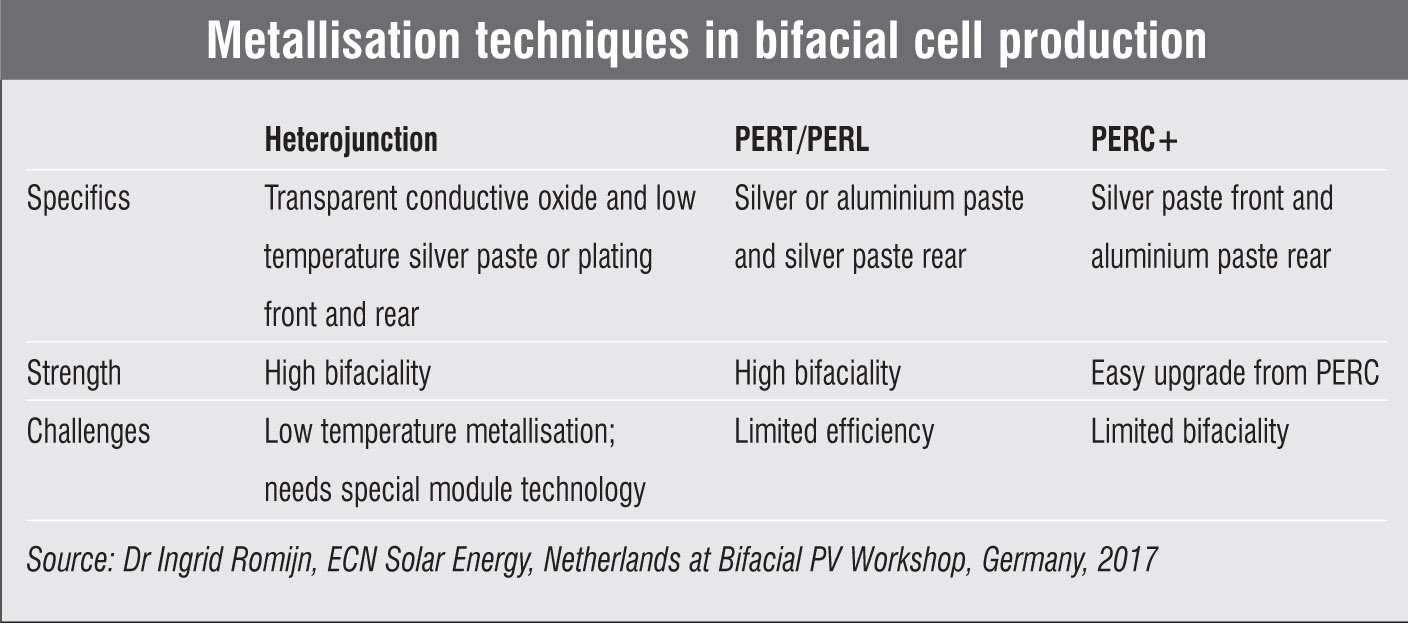

Bifacial modules have a glass-glass configuration normally to reduce the stress on the sandwiched cells and prevent moisture ingress. However, bifacial glass-backsheet modules are also becoming common, by making the backsheets transparent, instead of dyeing them white or black. Conventional monofacial cells have a fully metallised backside, while bifacial cells require selective metallisation in certain areas on the rear, to permit light to pass through and make it a collector. In traditional crystalline cells, aluminium is the chief component of the backside metal while screen-printed silver paste is used for contacts. Bifacial cells may use other metals like nickel or cobalt and a different metal deposition process. This may lead to an increase in the number of manufacturing steps, and hence, have an implication on the cost of production. However, higher costs can be offset by greater efficiency gains.

Traditional monocrystalline silicon cells are categorised as n-type or p-type, which is determined by the abundance or deficiency of electrons in the silicon wafer. Likewise, bifacial cells can also be n-type or p-type, depending on the silicon wafer that they are manufactured from. N-type silicon is made by adding atoms from phosphorus-like materials, which have one higher electron than silicon in their outer shell. As per the American Chemical Society, this electron does not bond with any atom and can move inside the silicon structure, which aids in the flow of current. P-type silicon, on the other hand, has atoms like boron. These have one electron less than silicon in the outer shell, which creates a vacancy in the structure, and are more prone to light induced degradation (LID). Majority of the monofacial cells sold worldwide are made from p-type silicon wafers due to their cost effectiveness when manufactured in large volumes. However, many manufacturers are also producing n-type bifacial cells due to their low susceptibility to LID, which leads to greater efficiencies.

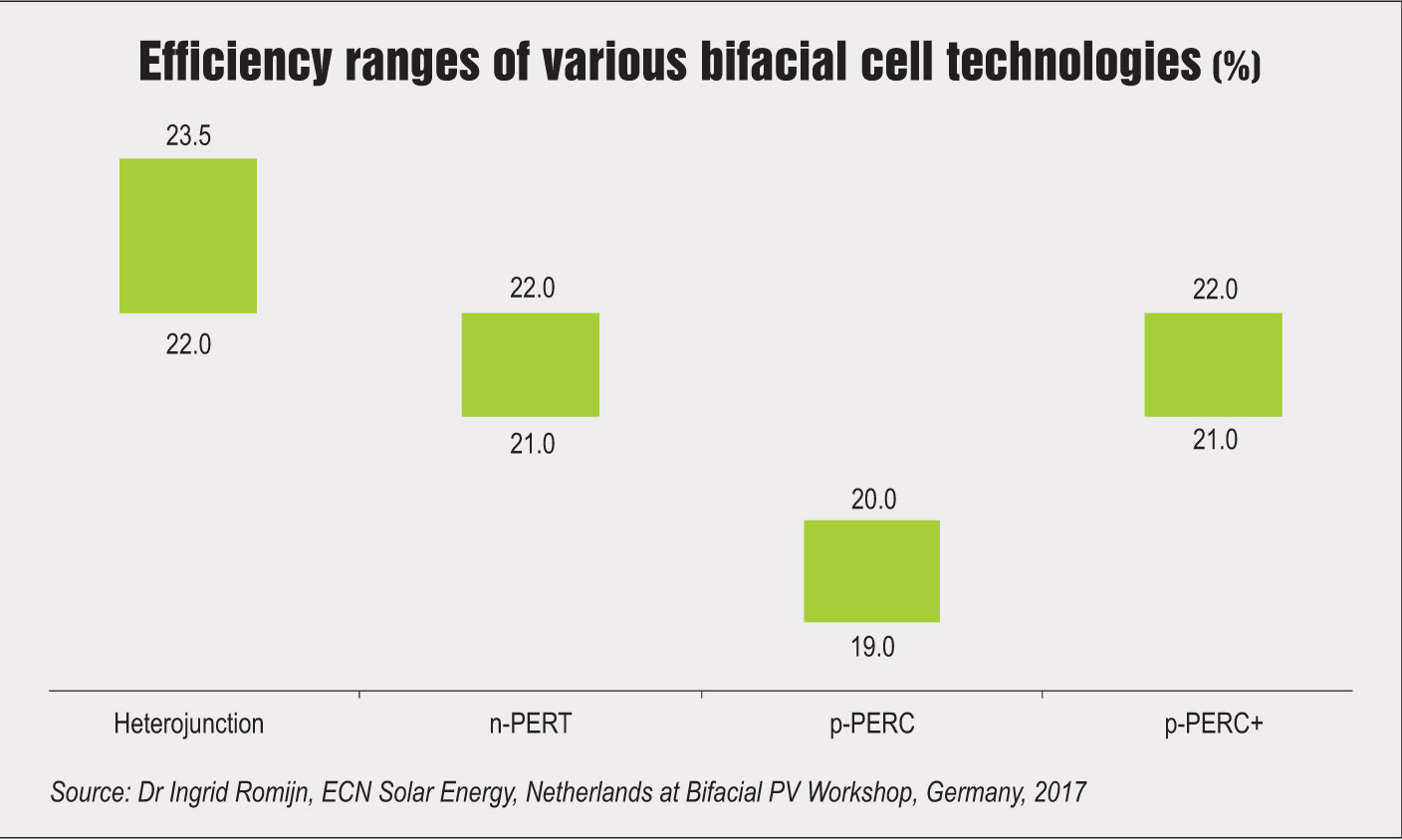

Research is being done to bring more innovation to conventional silicon solar cells. Technology enhancements on high efficiency passivated emitter rear contact (PERC) cells, passivated emitter rear locally diffused (PERL) cells, passivated emitter rear totally diffused (PERT) cells and heterojunction technologies (HT) to make them bifacial are under way on a massive scale. Different production processes, all aiming for lower manufacturing costs, have resulted in various cell architectures like BiSoN, with bifacial solar cell on n-type silicon, ZEBRA with stripes of n-type and p-type doping on the cell’s backside and PANDA, which was named after the collaboration that developed the cell.

Going forward, novel concepts like bifacial back contacts, selective contact cells and transparent metal oxide contacts are likely to result in greater efficiency gains. The market share of n-type silicon wafers will most likely increase due to greater demand for higher efficiencies. For the same reason, bifacial modules that use high efficiency PERC or HT cells will become more popular. It is expected that the slightly higher prices of these bifacial technologies will be offset by the increased energy generation over project lifetime.

Even with the obvious benefits offered by the various bifacial cell technologies, widespread adoption is dependent on the cost-benefit analysis and determination of the applications where different technology types are most effective. However, this analysis requires enormous volumes of actual field data, which is currently insufficient. In the near future, manufacturers and researchers are likely to channel their resources to collect data and compare technologies in terms of cost and efficiencies. Until that happens, it is premature to conclude which technology will be the most competitive from the huge variety on offer.