By Sarthak Takyar

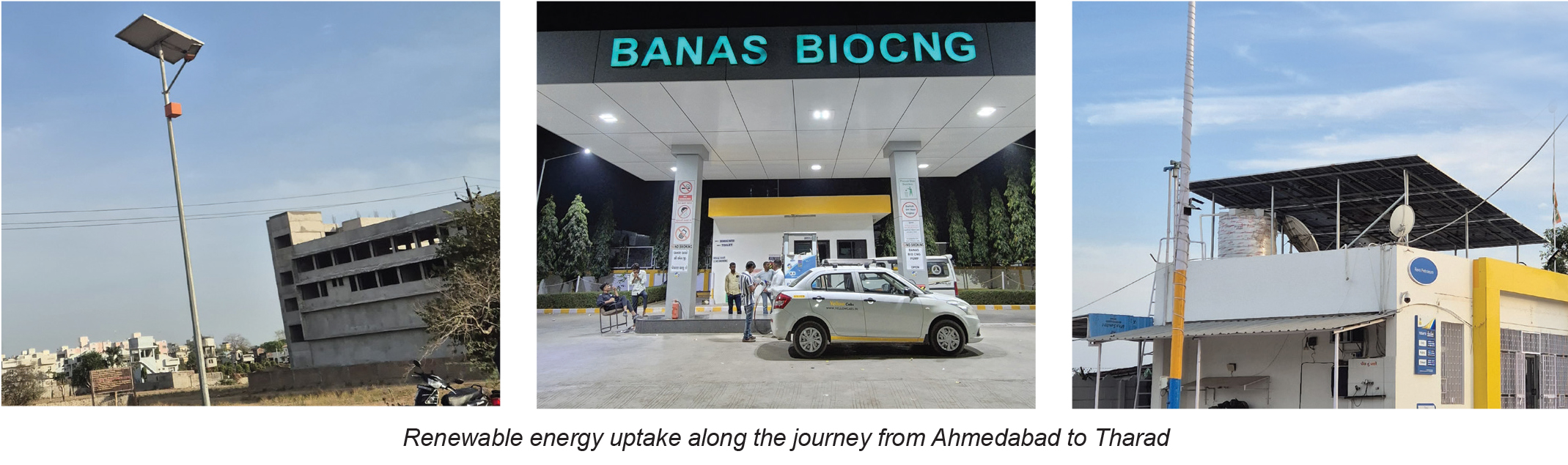

A site visit to a utility-scale solar project developed by ENGIE India at the Raghanesda Solar Park brought me back to Gujarat. For a renewable energy enthusiast, it is inspiring to visit a state that was an early adopter of renewable energy and is now a leader in its uptake. While travelling through Gujarat, one gets a glimpse of the efforts undertaken by the state to drive the energy transition. Numerous residential buildings with rooftop solar plants and solar street lights along the highway were a common sight during my road journey from Ahmedabad to Tharad district in north Gujarat. The House of MG, a heritage hotel in Ahmedabad where I stopped to enjoy a Gujarati thali, is powered by solar energy from a rooftop plant. In fact, even the cab journey was sustainable in a way, as the CNG car often stopped at compressed biogas refuelling stations run by Banas Dairy.

This journey was an interesting precursor to the site visit I had planned for the next day – to a 200 MW solar project developed by Electro Solaire Private Limited, a subsidiary of ENGIE India, in Raghanesda village. The project’s engineering, procurement and construction (EPC) was undertaken by Sterling & Wilson. The EPC contractor also handled the operations and maintenance (O&M) for two years, after which ENGIE India took over under its self O&M strategy.

The project uses monocrystalline modules, with a total of 630,525 modules installed. This project was won under the Gujarat Urja Vikas Nigam Limited (GUVNL) 1 tender and the power purchase agreement (PPA) was signed with GUVNL on August 26, 2019, with project commissioning on August 14, 2021.

Water scarcity leading to changes in O&M techniques

After a night’s stay at Tharad, another beautiful road journey awaited the next day to the Raghanesda Solar Park. I was accompanied by Sandeep Jadhav, Director – Operations, India (Renewables), ENGIE, who shared several key insights on the operational challenges faced by the team, changes in O&M techniques and the best practices they followed.

Jadhav shared that the project faced some operational challenges post-commissioning. The responsibility for providing water lay with the solar park. However, after two years of operating the solar plant, water scarcity issues in the nearby region became a significant issue, with water being available only for two to three months in a year. The lack of water during the peak generation period from January to June became a key challenge. To avoid generation losses, the company had to buy water from external sources at a higher rate.

The scarcity of water and the high cost of purchase also led to changes in O&M techniques. The operations team had earlier planned for 24 cycles of wet cleaning in a year, but had to transition to semi-automatic cleaning (the plant was not designed to be compatible with fully automatic cleaning). “With this transition, we were able to achieve a 75-80 per cent reduction in water usage, lower diesel costs for tractors, and a reduction in soiling losses as well. Due to these trends, overall, our total revenue increased by 1 per cent,” says Jadhav. The plant currently uses both dry and water-based semi-automatic cleaning, with three to four water-based cleaning cycles reserved per year.

O&M best practices

Pausing briefly to soak in the view of migratory birds across the marshy land, Jadhav continued to share the best practices that the O&M teams follow at the company’s different projects. In the initial phase of the project, the O&M team is involved in devising the costing model that is provided to the bidding team. The technology parameters are then planned, before selecting the equipment. When the construction phase begins, the O&M team is deployed at the site to supervise the quality of work and ensure smooth handover of the plant, in addition to engaging third-party players. This ensures that the plant starts generating electricity to its full commissioned capacity to avoid generation loss. The team also develops a breakdown impact analysis and mitigation matrix for all equipment in the solar plant. This serves as a guide for responding to equipment failures and outlining specific actions to be taken for each type of issue. “Before the plant begins operations, we have a certification programme called the “Competency Matrix”, which has three levels – competent, conquerer and champion. All employees at the site must pass the exam and have to undertake necessary certification according to their job profile. Until they get this certification, they are not allowed to work independently at the site,” says Jadhav.

F&S of the project and discussion points

Upon reaching the project site, Nitish Singh, the safety manager, gave a presentation on the safety protocols followed by them. After donning elaborate gear, including snake-proof boots, we took a round of the solar park. As the day was cloudy, the discussion shifted towards the accurate forecasting and scheduling (F&S) of renewable energy.

As renewable energy integration continues to grow, accurate F&S has become critical in ensuring grid stability and optimising power generation. ENGIE has developed a structured and data-driven approach to managing these challenges effectively.

Site managers play a pivotal role in ensuring that energy output aligns with both demand and grid requirements. On a typical day, Nikunj Kumar, the site manager, oversees this complex process. His responsibilities include continuous tracking of energy generation, weather patterns and grid conditions to make informed operational decisions; leveraging advanced meteorological data to anticipate fluctuations in solar or wind energy output and adjust scheduling accordingly; ensuring energy supply matches demand by coordinating with grid operators and making the necessary adjustments to generation patterns; adhering to regulatory requirements for scheduling and forecasting; and minimising penalties and improving overall grid stability.

This proactive approach not only enhances operational efficiency but also helps mitigate the challenges of intermittency that often accompany renewable energy sources. The site leverages advanced forecasting models, artificial intelligence-driven analytics and real-time data to ensure the asset is utilised optimally. To help in grid stability, the solar site has set up a reactive power compensation of 64 MVAR with an investment of Rs 70 million-Rs 75 million, which has now become mandatory for all projects.

The F&S of renewable energy is a not a simple process as per the new regulation imposed by the CEA. The O&M team at the site overcomes this challenge through effective communication with a qualified coordinating agency (QCA) to ensure real time SCADA reporting, timely updating outages and getting more accurate forecasting data from global agencies.

Typically F&S of solar energy is severely affected during the monsoon period where the passing clouds impact the generation which can not be predicted through a meteorological station. This becomes a key challange for managing intraday schedules where developers have an option to revise a plant schedule only in the 7th or 8th time block.

This results in penalties for deviations that fall below the 10 per cent deviation band, which applies to projects connected to the interstate transmission system network. In fact, it is not just day-ahead forecasts; even intra day forecasts are often difficult to make accurately, especially on rainy days. During such periods, penalties on solar plants can be upto 4-5 per cent of the total revenue. Till 2022 (before the change in regulations), the penalties accounted for just 0.2 per cent of total revenue. This has increased over the last two years as regulations have become more stringent. Deviation bands have decreased from 35 per cent to 15 per cent and solar developers are incurring penalty of 100 per cent revenue above 15 per cent error band.

This raises pertinent policy-related questions that need to be addressed. One, are the deviation bands and penalties justified? Especially during extreme weather events, despite after using advanced tools, it is difficult to accurately forecast generation and developers incur revenue losses. Two, is it justifiable to not buy the extra renewable energy generation beyond the deviation band? Additionally, if the generation is not bought (either more or less than the deviation band), is it a misuse of the must-run status?

The grid operator’s perspective is also crucial. Does the intermittency of renewable energy – leading to excess or less generation – truly warrant strict penalties? In addition, if there is extra generation, can developers mitigate their loss by selling it on the power exchanges?

To avoid penalties, apart from using advanced forecasting tools, a key solution is for developers to add a storage component. However, despite the developers’ interest in doing so, it is not possible if the projects are won through non-storage tenders. Thus, should a policy update now allow developers that won projects in standalone solar tenders to set up storage capacity to avoid deviation penalties?

While ENGIE India’s Gujarat solar site has not faced curtailment issues, Jadhav shared that their solar plants at other locations can experience curtailment of up to 60-70 per cent of the day’s generation. This occurs when the grid operator cites that there is “no demand”, despite the must-run status in place for renewable energy plants.

Parting thoughts

ENGIE India currently has a portfolio of over 2.3 GW across 22 projects, with 1.1 GW operational in seven states and 1.25 GW under construction. Going forward, it plans to develop 7 GW of renewable capacity in India by 2030. The O&M team is preparing for the O&M of these projects and is also partnering with research institutes to hire skilled labour.

After long discussions, it was time to leave the site and head back to Ahmedabad airport. On the way, we stopped at a local school for the inauguration of a corporate social responsibility initiative undertaken by ENGIE India. Overall, it was an enriching experience to witness energy transition in action and see how private developers are engaging with the local communities.

Ultimately, it is the motivation of the people that drives the sector forward – a sentiment clearly reflected in conversations with the O&M team. “I am motivated each day, knowing my work is making a difference by promoting more renewables, contributing directly to the fight against climate change, helping reduce greenhouse gas emissions and making a positive impact on communities,” says Jadhav.