With the rapid pace of solar power deployment being witnessed in India, operations and maintenance (O&M) services have become increasingly important to the entire solar plant value chain and are not just a cleaning activity any more. As more plants are being commissioned and operational experience is widening, it is giving rise to knowledge about possible faults in a solar project. Thus, O&M best practices need to be deployed considering that the performance of and the resulting revenue from these solar projects are deeply impacted by different types of losses incurred due to environmental/technical reasons.

Losses and other challenges

While we want to harness maximum energy from a solar power plant, it is important to know about the kind of losses that can occur during operations. Some of the major plant performance issues are attributed to thermal and soiling losses. In regions with higher temperatures, thermal losses can go up to 8 per cent while losses due to soiling can reach up to 25 per cent in arid regions with only seasonal rain and dust. Thus, site conditions and soiling losses need to be factored in while devising a business plan. Although module cleaning is done to minimise soiling losses, the level of impact depends on the frequency of cleaning, water quality and control on dusty surroundings. For instance, at sites located close to mining activities, modules have to be cleaned at least once a week. If not checked, soiling could lead to a loss of up to 30 per cent. To prevent soiling, there is a need to have the water line in place prior to commissioning of the plant. It can also be controlled by using data analytics for better understanding soiling-related conditions in the micro-environment of solar panels, and methodical cleaning cycles with diligent reporting. The dust detection system (DDS) is one such tool that is used for monitoring by integrating it with weather stations and cameras. The DDS helps in real-time revenue loss monitoring by measuring the energy loss by comparing the output differences of dusty and clean panel. It also provides a cleaning time forecast for operators to maximise the revenue gains for investors.

Other factors that lead to losses are photovoltaic (PV) module mismatch due to modules with dissimilar characteristics being connected together, non-functional PV modules, tolerance of rated power, and potential-induced degradation (PID). PID is a new and very serious problem in the PV industry. It can result in yield losses of 20 per cent or more in the form of current leakage caused by surface polarisation in modules. Based on the way conventional PV systems work, voltage differences occur between the frames and the solar cells of a module. This can lead to undesired leakage currents, which can decrease the performance of the cells, and are likely to occur in the rainy season. This is an unwelcome side effect of the high voltages that are typical of today’s PV plants. Under PID, the open circuit voltage gets affected and this results in poor performance of cells in a solar module. Another challenge is presented by haze. Irradiance from satellites is used to assess system performance. Silicon sensors on rooftops are not very reliable, thus a combination of satellite data and ground data is used to estimate the expected generation. A drawback of satellite data is that it varies from ground data considerably when there is haze.

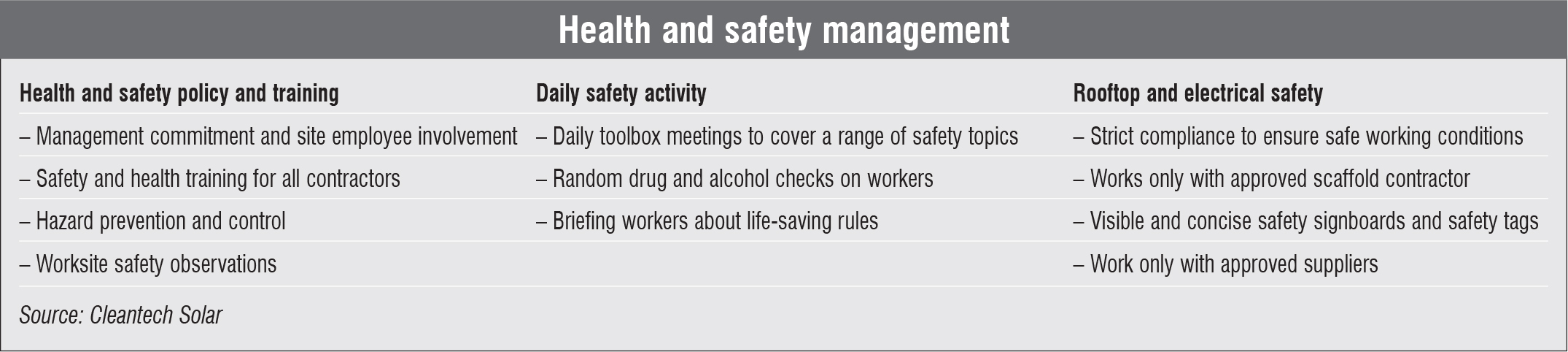

Apart from these challenges, there are multiple health, safety and environment hazards while carrying out O&M at solar PV sites. These include fall, electrical, injury and fire hazards. There is a need for training the manpower in order to carry out work safely. However, there has been a gradual shift in recent years in terms of how safety is viewed, and best practices to ensure safety are now being given much more emphasis.

Apart from these challenges, there are multiple health, safety and environment hazards while carrying out O&M at solar PV sites. These include fall, electrical, injury and fire hazards. There is a need for training the manpower in order to carry out work safely. However, there has been a gradual shift in recent years in terms of how safety is viewed, and best practices to ensure safety are now being given much more emphasis.

Project installation and O&M

Quality of installation is very important for determining the future performance of a solar project. Every project should be monitored during the construction phase and all issues at the installation stage should be taken care of by a technical on-site team. Even if small issues such as reverse polarity go unchecked, they can cause a fire at the site. Thus, regular inspection and testing should be undertaken in the form of visual inspection, thermography, IV measurement at the site as well as the laboratory, and electroluminescence.

Significant operating costs and project downtime can be avoided if proper project equipment and design practices are followed. To this end, some key points should to be kept in mind to ensure quality of installation. For instance, there should not be any sharp edges around the project equipment as these could cause wire damage and lead to insulation resistance issues. To prevent damage, pre fabricated curve bends can be used. In addition, cables should be effectively laid to ensure they are not hanging or exposed. In case cables are left exposed in a rooftop solar system, there could be damage due to high temperatures. These issues can mostly be rectified at the installation stage. Moreover, engineering, procurement and construction specifications for contractors include installing cable trays at specific distances. The cable trays should be properly sized. It is also important to avoid the impact of shading to prevent loss in output.

Significant operating costs and project downtime can be avoided if proper project equipment and design practices are followed. To this end, some key points should to be kept in mind to ensure quality of installation. For instance, there should not be any sharp edges around the project equipment as these could cause wire damage and lead to insulation resistance issues. To prevent damage, pre fabricated curve bends can be used. In addition, cables should be effectively laid to ensure they are not hanging or exposed. In case cables are left exposed in a rooftop solar system, there could be damage due to high temperatures. These issues can mostly be rectified at the installation stage. Moreover, engineering, procurement and construction specifications for contractors include installing cable trays at specific distances. The cable trays should be properly sized. It is also important to avoid the impact of shading to prevent loss in output.

The solar sector is currently focusing more on capacity expansion as compared to quality of projects. However, as plants become older and the scale of installed solar capacity increases, it will become essential for developers to adopt new O&M practices to ensure good results. This will lead to the emergence of large-scale O&M players with the capacity to offer cost-effective solutions. Going forward, while new technologies drive changes in the solar industry through performance improvement, innovations in solar equipment alone will not guarantee lifelong high energy yields. Instead, diligent O&M by trained manpower and the use of real-time performance monitoring software will help in generating the required returns from projects. In sum, with the adoption of best practices in solar O&M, not only can cost savings be achieved but long-term output from solar plants can also be optimised. n

Based on a presentation by Rupesh Baker, Head, O&M (India), Cleantech Solar; and Sanjay Narula, Vice- President and Head O&M, Quality and Technology, Hindustan Cleanenergy at a Renewable Watch conference on “O&M for Solar Plants”