By Aastha Sharma

Biomass co-firing has become a viable transition pathway for India’s coal-based thermal fleet, enabling emissions reduction without extensive plant modifications. By replacing a portion of coal with biomass pellets, thermal power plants (TPPs) can lower their carbon intensity, reduce local pollutants and divert agricultural residue away from open burning. This offers a dual advantage: cleaner generation and a practical solution to the persistent challenge of managing paddy straw and other crop waste, which contributes heavily to seasonal air quality deterioration in the northern region.

Biomass pellets, produced from compressed agricultural residues such as paddy straw, husk, shells and horticulture waste, provide a uniform and energy-dense fuel suitable for blending with coal. Their consistent size and lower moisture content improve both handling and combustion efficiency. Alongside this, torrefied charcoal derived from municipal solid waste (MSW) has emerged as an additional fuel stream under the revised policy framework. Through controlled heating without oxygen, MSW-based material becomes drier, more brittle and more energy-rich, bringing its combustion characteristics closer to coal. Based on boiler design and original equipment manufacturer (OEM) guidance, plants may use non-torrefied, semi-torrefied or fully torrefied pellets, creating flexibility in fuel choice while expanding the pool of usable biomass resources.

Policy framework

As per government estimates, India generates around 750 million metric tonnes (mmt) of biomass annually, of which nearly 230 mmt is surplus agricultural residue. In addition, about 150,000 metric tonnes of MSW is generated every day in urban centres, leaving nearly 14 mmt per year unprocessed.

Over the past few years, several policy measures have been introduced to accelerate biomass co-firing in TPPs. The Ministry of Power (MoP) initiated the effort in November 2017 with its first policy mandating 5-10 per cent biomass pellet blending in pulverised coal-fired boilers. This mandate was expanded in October 2021 to cover all TPPs and was reinforced in the Union Budget 2022, which reiterated the need for 5-10 per cent co-firing.

To streamline procurement and address supply chain constraints, the MoP established the Sustainable Agrarian Mission on use of Agri-Residue in Thermal Power Plants [SAMARTH] Mission, focused on pellet production, storage and logistics. A subsequent policy revision in 2023 introduced benchmark pricing for biomass pellets, effective January 2024, to balance producer viability with affordability for power plants.

In November 2024, the MoP notified benchmark prices for non-torrefied biomass pellets for the northern (excluding the National Capital Region [NCR]) and western regions at Rs 2.27 and Rs 2.24 per 7,000 Kcal respectively, excluding GST and transport, to correct regional cost variations.

Parallel to this, the National Bioenergy Programme, notified in 2022, has been supporting SAMARTH’s implementation. The Commission for Air Quality Management (CAQM) has also issued directives requiring all captive thermal plants in the NCR and adjoining areas to adopt biomass co-firing, prioritising paddy straw, with a minimum 10 per cent target by December 31, 2023.

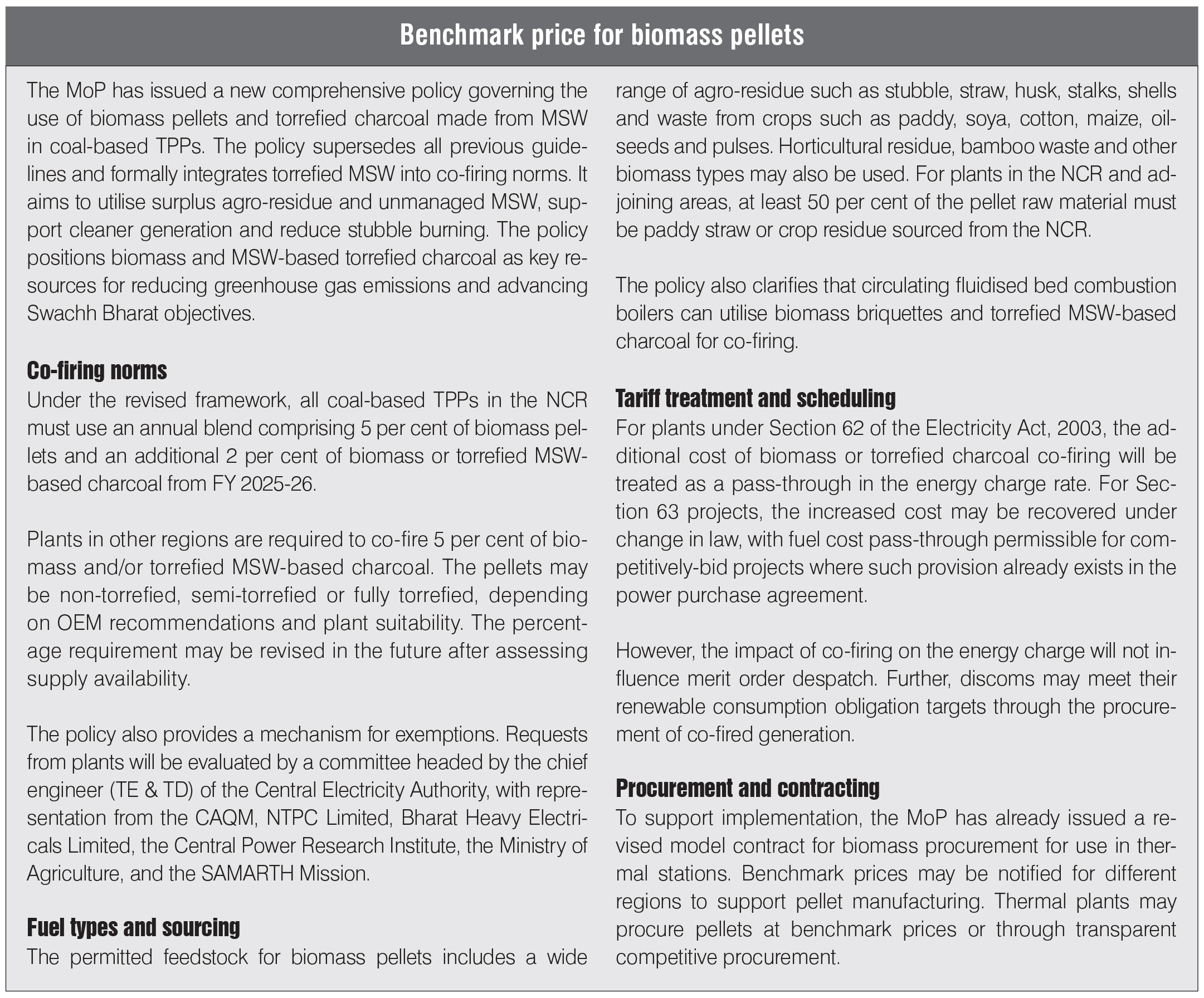

Recently, in November 2025, the MoP issued a comprehensive framework that supersedes all earlier orders. The updated policy integrates biomass pellets and torrefied MSW-based charcoal into a unified approach, linking residue utilisation, air quality improvement and decarbonisation with clear norms for blending, procurement and compliance.

Progress so far

As per the CAQM, a total of 71 TPPs across the country, including 11 units in the NCR, are now co-firing biomass with coal as of August 2025. This expansion has yielded notable environmental gains, including the avoidance of 3.477 mmt of CO2 emissions, an estimated 80 per cent reduction in stubble burning in Punjab and Haryana, and measurable improvement in Delhi-NCR’s seasonal air quality.

The co-firing initiative, which began in 2021 with a 5-10 per cent biomass mandate for NCR plants, has since broadened in scope. In 2025, the CAQM extended similar requirements to brick kilns in non-NCR areas of Punjab and Haryana, with a target of achieving 50 per cent biomass utilisation by 2028. By converting agricultural residue such as paddy straw into a fuel resource, biomass co-firing provides both emissions reduction and an alternative to open-field burning.

Alongside biomass co-firing, the CAQM is advancing complementary interventions, including artificial intelligence-enabled vehicle monitoring, drone-based compliance checks and stricter dust-control protocols at construction sites to reduce particulate emissions.

Challenges

Challenges

Biomass co-firing in coal-based boilers presents multiple operational challenges due to the differing characteristics of the two fuels. Variations in energy density, moisture levels and ash composition can affect combustion stability and overall boiler performance. Biomass typically carries higher moisture and lower calorific value than coal, making pretreatment steps such as drying, size reduction and pelletisation necessary, which increases operating costs. Its ash content can also lead to slagging, fouling and corrosion, particularly at higher co-firing ratios.

Mixed implementation across states shows that several plants continue to miss co-firing targets due to inconsistent pellet supply, seasonal residue availability and storage limitations during monsoon months. Some stations have also reported boiler-related constraints, including slagging and fouling at higher co-firing ratios. These operational and supply chain gaps highlight the need for stronger vendor capacity, tighter monitoring and more stable procurement systems to ensure reliable adoption.

The way forward

Scaling co-firing beyond current levels will depend on stronger supply chains, wider pellet manufacturing capacity and consistent feedstock availability across regions. The policy framework anticipates periodic revisions to blending requirements, which will likely rise as fuel supply stabilises and torrefied MSW production matures. Strengthening procurement through benchmark pricing, long-term contracts and regional aggregation models will be key to ensuring uninterrupted fuel flow to thermal plants. On the operational side, greater standardisation of boiler modifications, continued OEM support and adoption of monitoring systems can help improve reliability at higher co-firing ratios. With rising regulatory focus from agencies such as the CAQM and growing demand for cleaner generation, co-firing is expected to evolve from a compliance requirement into a mainstream component of thermal plant operations.